process involving many functions within the company, each

contributing a perspective to the assessment, financial,

management of changes to the system, inspection and

associated personnel and equipment requirements,

environmental and social implications. The important thing

is: you need data to assess the condition of pipelines – so

inspections are obviously central to integrity management.

What is Nord Stream doing in terms

inspections and what has Nord Stream done

so far?

For identified risk scenarios, an Integrity Management Plan

is designed: which surveys and inspections are needed to

gather what data; how to properly assess the results and

what remedial measures and repairs are needed in each

case, including what preparation is needed to ensure repair

readiness.

Inspections are undertaken regularly to gather data on

the condition of the pipeline and its components, and the

subsequent data is analysed by us and our contractors in

order to assess whether any remedial work is required.

We conducted the baseline surveys, both external

by ROV and internal with an intelligent pig, in 2013. Both

confirmed that the pipeline is in ‘factory new’ condition.

Last year, we conducted the first follow-up external

inspection by ROV, both visual and geophysical. We

compared the results to the baseline to see how the pipeline

is behaving under continuous operation conditions. As

expected, the pipeline is settling into the seabed. We also

checked for foreign objects in the vicinity of the pipelines

and found nothing unusual.

As expected, we are seeing that the pipeline is

overgrown with small mussels in certain depths, forming an

artificial reef for the species.

We will conduct further external surveys in summer 2015,

to continually monitor the geophysical stability and position.

How is Nord Stream setting up its repair

readiness and capabilities?

Thanks to a comprehensively engineered design; a high

standard of material used for pipeline construction; carefully

planned routing; and regular inspection and maintenance

activities, a significant pipeline repair event is not expected

during the pipeline system’s design life of 50 years.

For repair and remedial works, we are putting a lot of

efforts into readiness.

We introduced a repair preparedness strategy designed

to guarantee a level of preparedness and response capability

in the event of an incident, to ensure that the asset can be

recovered safely back to its normal operational performance

in an efficient and reliable manner.

We started with upfront development of procedures

for a spectrum of possible repair cases and set up an

organisational structure including internal functions for

repair and qualified and trained personnel with the expertise

to implement repairs in accordance to best industry practice.

An important part is also ensuring the availability of

necessary spares and upfront investment in long lead items

of repair equipment to be stored and maintained for the

pipeline operational life. We are storing a variety of spare

parts and 450 (equivalent to approximately 5.5 km) spare

pipes near the landfalls for repair cases.

Agreements with appropriate industry specialist

contractors are also a key element.

Who is Nord Stream partnering with to

ensure repair capabilities?

Nord Stream has secured the services of specialised offshore

construction company Saipem as Main Repair Contractor

(MRC).

The MRC, together with Nord Stream’s own in-house

technical specialist support, has conducted significant

levels of detailed engineering to develop the necessary

operational procedures and definition of equipment needs

to ensure that, in the event of an incident, MRC is ‘ready to

act’ to return the pipeline system back to full operational

capacity. Saipem has the inherent advantage that it was the

main contractor involved in the construction of the offshore

pipeline system and therefore has the familiarity. It can also

potentially provide the necessary types of marine vessel

spread to undertake recovery and repair of the damaged

section of the pipeline.

Another significant element of the Nord Stream Repair

Strategy is its membership to the Pipeline Repair and Subsea

Intervention (PRSI) Pool,

which is administered

by Statoil. Through the

membership, Nord Stream

has access to a range of

specialised services and

equipment technically

suited for performing

large diameter subsea

repairs, including a

remotely operable habitat,

pipeline support frames

and auxiliary support

systems which were

already deployed for

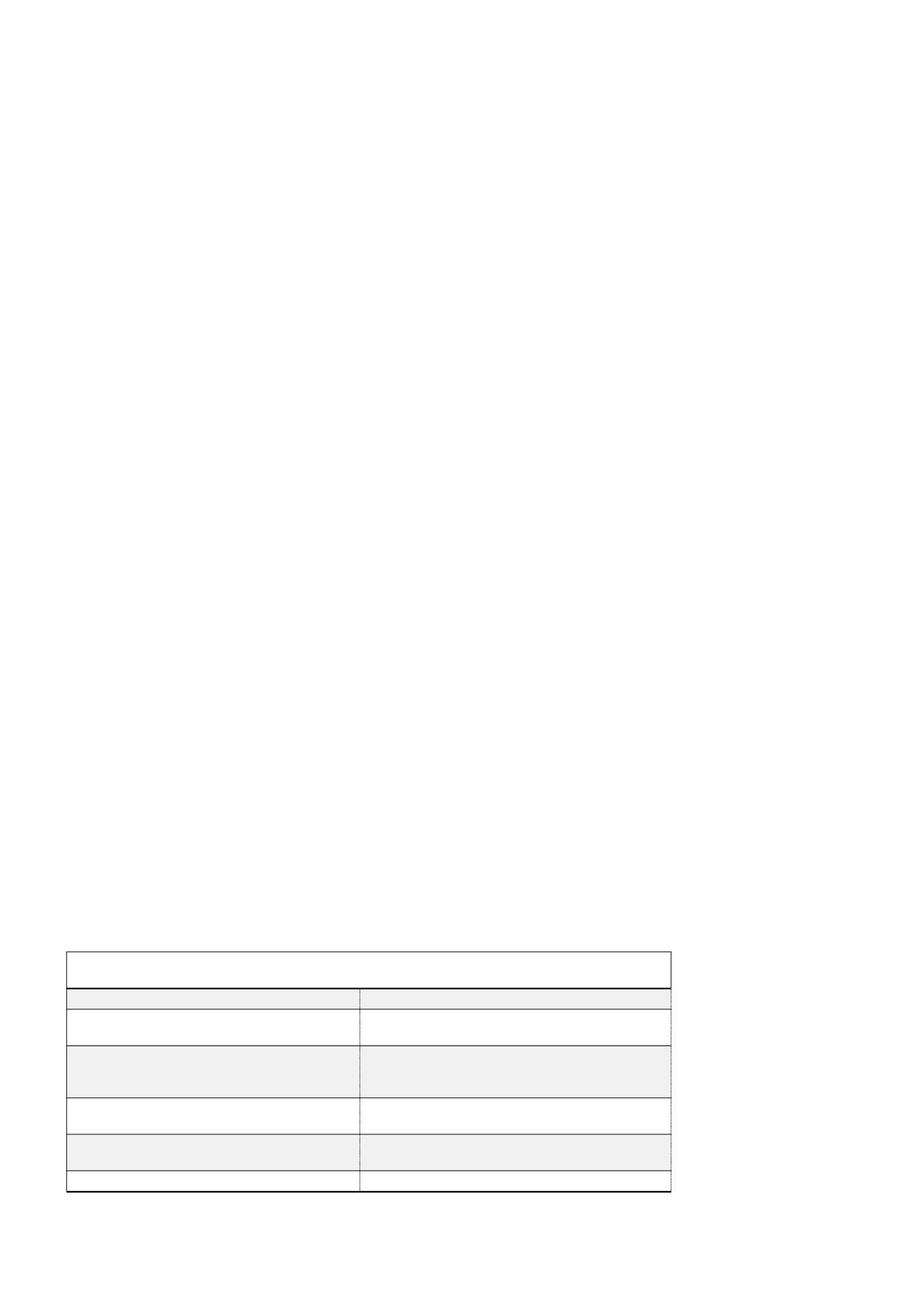

Table 1. Different repair service types defined in the repair strategy, for which procedures were developed

and specialised partners and equipment are contracted

Type of service

Reference description

Type 1

FIRST REACTION + DAMAGE ASSESSMENT

External inspection

Type 2

MAINTENANCE/REMEDIAL WORKS

e.g. rock placement for stabilisation; free span correction;

pipeline protection; anode replacement; other

Type 3

LOCAL DAMAGE REPAIR

Externally fitted 48 in. dia. repair clamp

Type 4

SHORT DAMAGE REPAIR

Section replacement up to 2 pipe joints ~24 m

Type 5

LONG DAMAGE REPAIR

20

World Pipelines

/

AUGUST 2015