F

ollowing the construction of the Nord Stream

Pipeline from 2010 through 2012, Nord Stream AG

has transitioned from being a project company

to the operator of the 1224 km twin pipeline gas

transportation system connecting Portovaya on the Russian

Baltic coast with Lubmin, Germany. As an operator, Nord

Stream AG is focusing on safely and reliably maintaining its

main asset: the gas transportation system.

How is Nord Stream approaching integrity

management for its pipeline?

Now that we are in the operations phase, integrity

management – preserving the asset for long term operation

– is the central engineering function within Nord Stream.

We view integrity management as a holistic process,

covering functions within the whole company, from

compliance through financial departments. We began

setting up the operations-phase integrity management

during the project phase and it follows a standard

quality process: Plan-do-check-act.

The first thought in terms of integrity

management is: what could happen that

endangers integrity, what would be the

consequences and what is required to

remedy the situation? We conducted

a risk assessment, which in itself is a

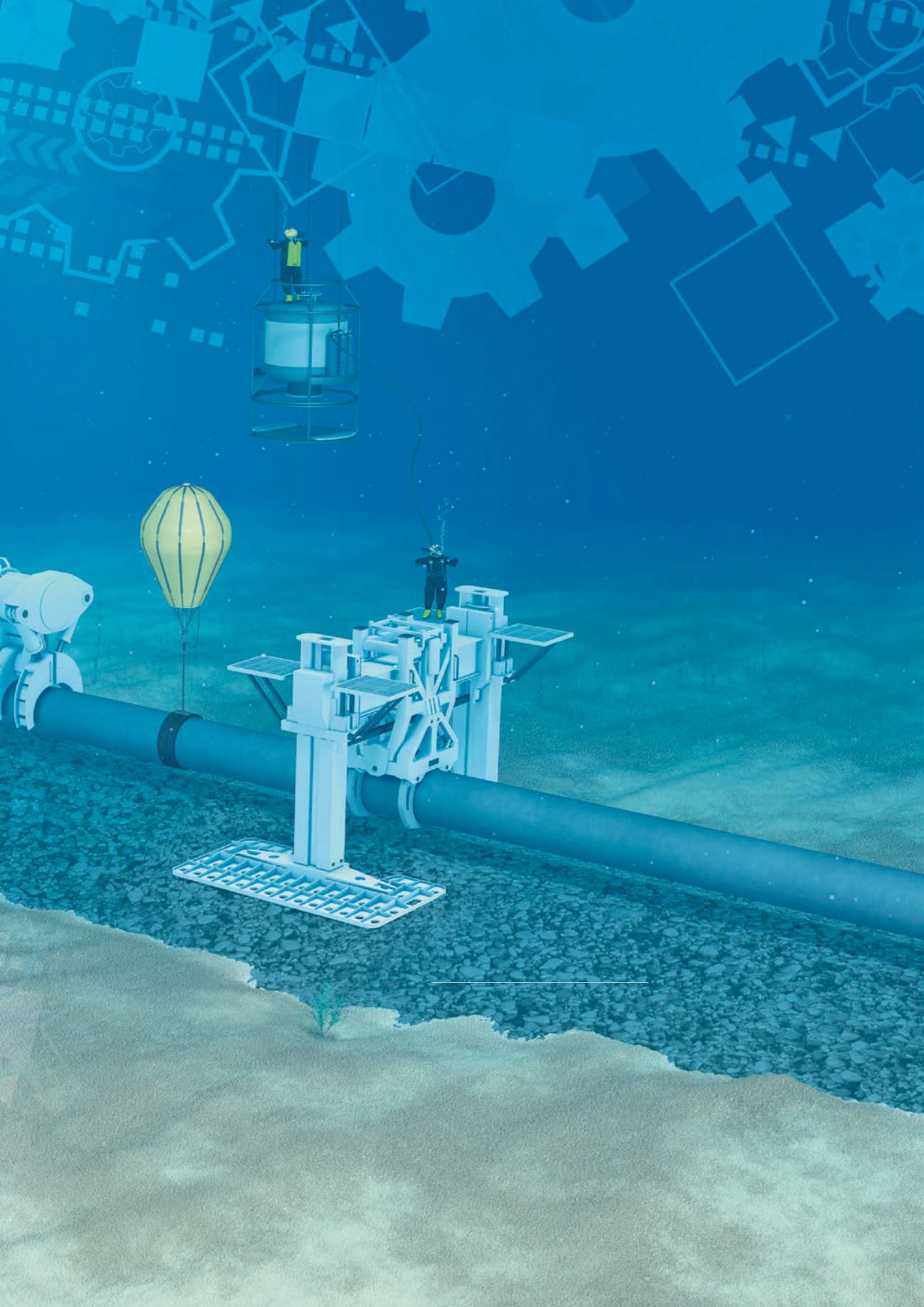

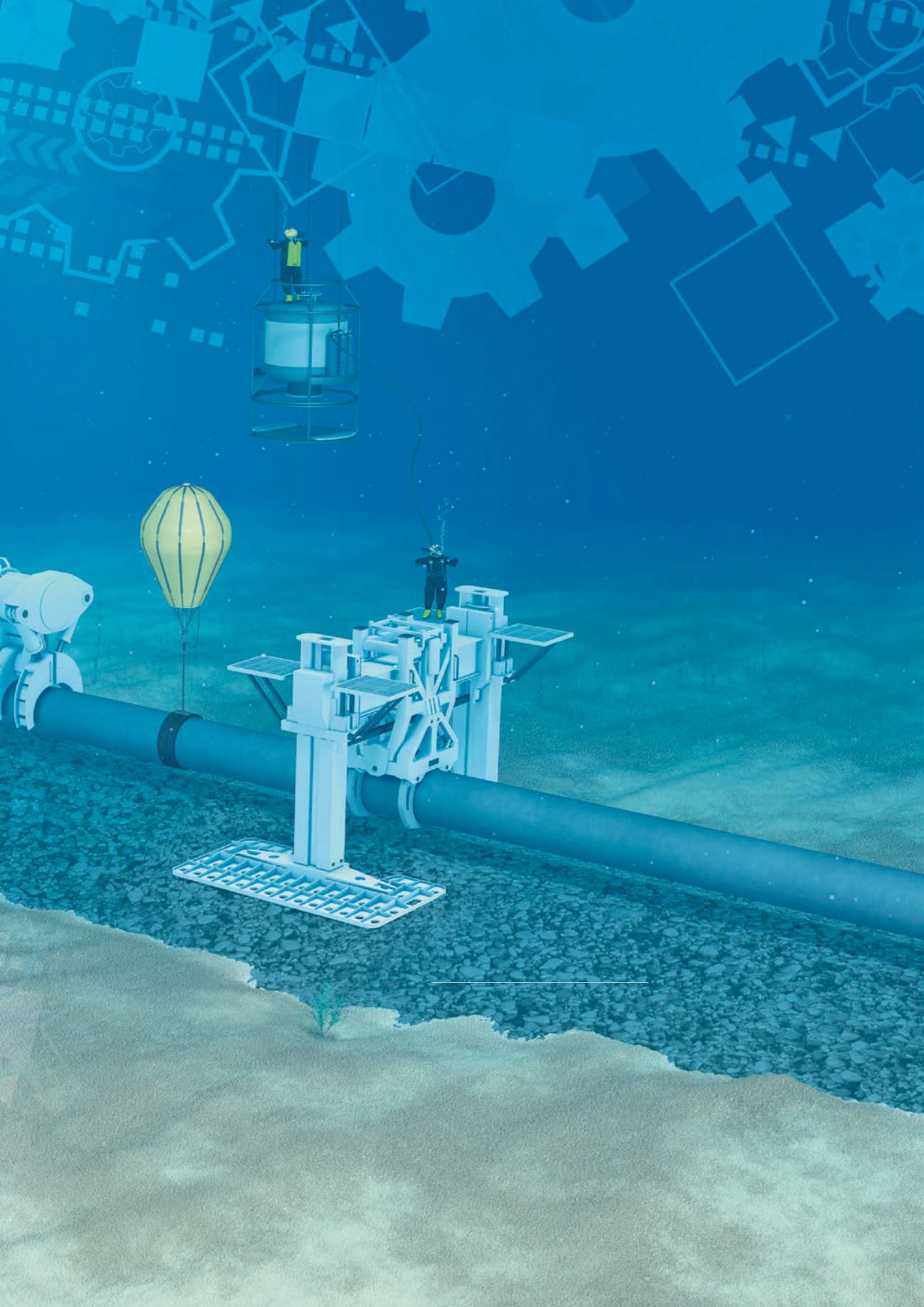

Figure 1.

Statoil administered PRS

hyperbaric welding system, as used

for HWTI on Nord Stream Line 1 and

2 during their construction.

19