needed – within energy dissipation

limits - to fully unload the conveyor

before maintenance work commences.

“Mine operators believe, with the

use of the RDBK, a conveyor will be

held in place regardless of an event

failing,“ the company said in a press

release. ”Also offloading the conveyor

is a less complicated process, which

permits maintenance work to be

completed quickly and reduces

downtime.“

Replacing fatigued

dragline boom clusters

BMT WBM has deployed its

DuraCluster modification and repair

scheme at a major opencast coal mine,

replacing a number of fatigued boom

clusters. According to the company,

the system improves the fatigue

performance of cluster joints on

existing tubular dragline boom

designs.

After the DuraCluster has been

installed, it lowers maintenance and

inspection workloads and also reduces

the problem of long-term fatigue

cracking associated with the existing

cluster design.

The log booms of draglines

comprise a number of tubular chords

with interconnecting lacings welded to

the chords at cluster joints. Stresses are

concentrated at the cluster joint

weldments and, over time, fatigue

cracking becomes endemic. BMT’s

methodology prevents the need to cut

and replace windows in lacings by

removing the problematic design

detail and improving load paths.

Furthermore, DuraCluster can extend

the fatigue life of dragline booms by

reducing the stress concentrations.

“A boom replacement can cost in the

region of US$20 million and would

require a three month machine outage,”

explained Charles Constancon, Director

of Canadian Services at BMT WBM.

“With BMT’s modification and repair,

the cluster design can be upgraded in

around one week per cluster,

depending on the extent of chord repair

required, while multiple clusters can be

modified simultaneously. With

equivalent repair costs reduced to

approximately US$2 million, this is an

extremely attractive incentive for

mining companies. While DuraCluster

provides a step change in life to

cracking for tubular boom construction,

it is equally applicable to tubular

masts.”

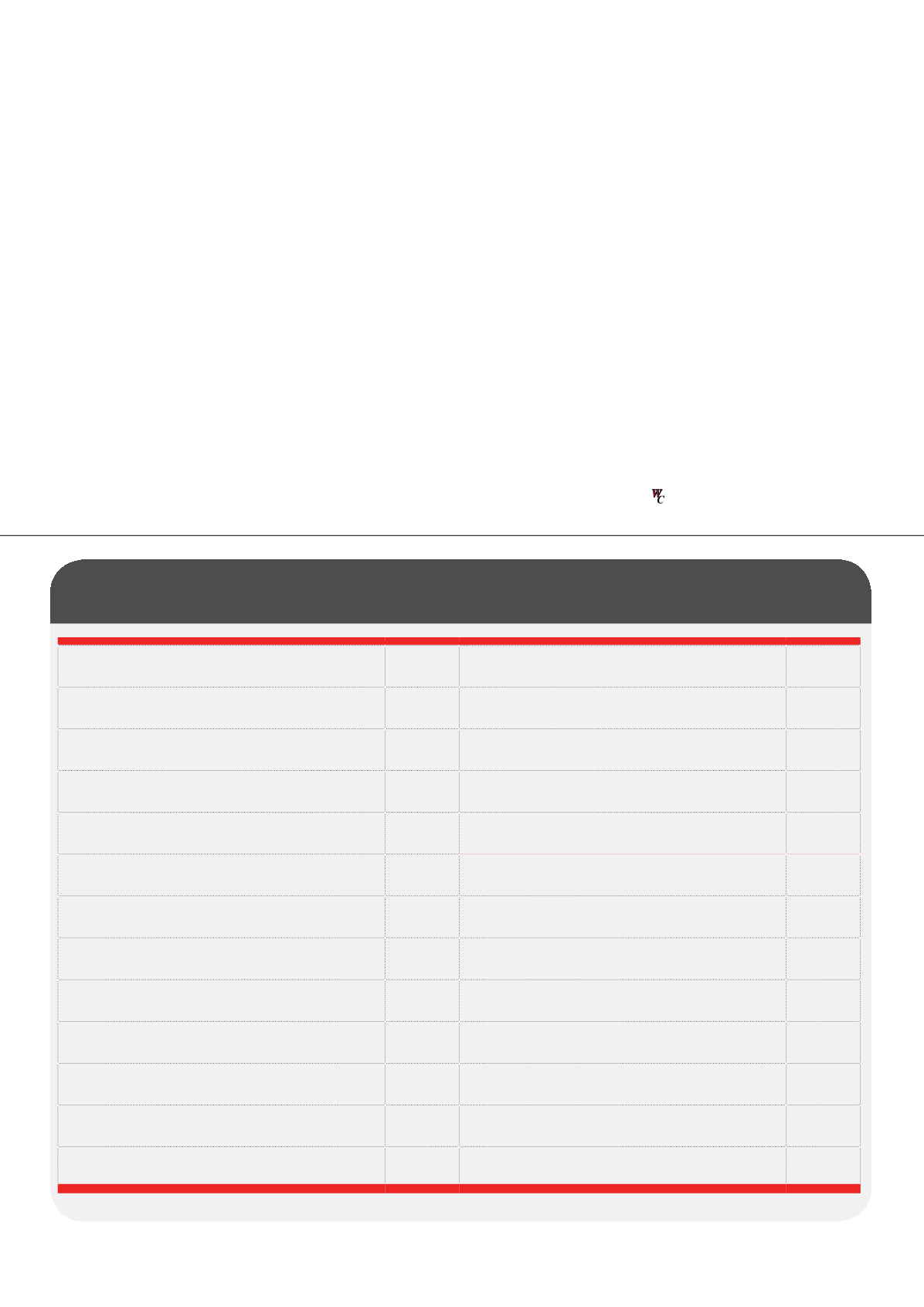

ABB

4

J.H. Fletcher & Co.

39

AIMEX

49

Joy Global

2

Ampcontrol

41

Liebherr

57

BASF

17

Loesche

IFC

Cincinnati Mine Machinery

36

McLanahan

74

Classic Motors

54

MMD

13

Coaltrans Japan

69

Motion Metrics

7

CSL Group

11

Peterson Filters

83

Derrick

OFC, 71 Polydeck Screen Corp.

79

Heyl & Patterson

59

Realtime Instruments

63

IronPlanet

50

Sandvik

OBC

James A. Redding Co.

19

Siemens

9

Jennmar

IBC Swire CTM Bulk Logistics

21

Advertiser’s Index

88

|

World Coal

|

June 2015