and repair activities, process vessel pressure testing, subsea

hydrotesting and process tubular hydrotesting activities.

The primary object of the Clariant invention was to

provide a range of simple to use, single-use, hydrotest

formulation systems with strong oxygen scavenging properties,

biocidal properties to negate any corrosion due to biological

activity, corrosion inhibition due to adsorption to the metal

surface and visual leak detection due to the presence of a

dye. This has also been formulated in an environmentally-

acceptable package, as legislated by many different regulatory

bodies worldwide (for example, CEFAS, NICNAS, TSCA, DSL,

etc.). This unique combination has superior performance to

formulations and individual chemicals disclosed in the prior

art. Another objective was to provide a formulation suitable

for application under extreme conditions, such as very high

salinities as well as high (up to 100°C) or low temperatures

(down to 0°C), which are sometimes encountered during

the hydrotesting of equipment. The formulations can be

ubiquitously used in all types of hydrotest fluid matrices, such

as seawater, drill water, potable water, river water, pond water,

lake water, aquifer water, produced water and brines.

The new PRESERVAN products comprise tailored

formulations of:

)

For corrosion protection, a quaternary ammonium

compound, specifically chosen for its superior

biodegradability.

)

An oxygen scavenger.

)

Optionally, an appropriate biocide (for example, DMDM

hydantoins or Dazomet).

)

An environmentally-acceptable dye.

There are many benefits to using combination products;

these have been proven in multiple extensive tests and field

applications. Single-blend products decrease complexity

– one product and one injection point – and also reduce

chemical movement, thus improving logistics and safety. The

high level of performance offered by these multi-functional

products is equivalent to dosing with individual products

separately; treatment time and equipment costs are also

reduced. Finally, there are no chemical compatibility issues, as

the ‘cocktail’ of chemicals are already combined in one fluid.

Extensive testing was performed on this enhanced

technology in order to deliver the best, most sophisticated

products for even the most demanding hydrotest applications.

Employing in-house application development testing

procedures (based on industry standards such as API and

NACE), orbisphere testing was used to measure and record

dissolved oxygen concentration, and a linear polarisation

resistance (LPR) electrochemical technique was used to

measure and record fluid corrosivity and corrosion protection.

Results from these tests showed that PRESERVAN rapidly

reduced the dissolved oxygen concentration to below 10 ppb

within 12 mins at 25°C and 16 mins at 4°C (Figure 1).

Using the LPR corrosion monitoring technique, PRESERVAN

quickly decreased the corrosion rate in the first hour to

0.01 mm/yr and stabilised at 0.0027 mm/yr, representing

99.5% inhibition (Figure 2).

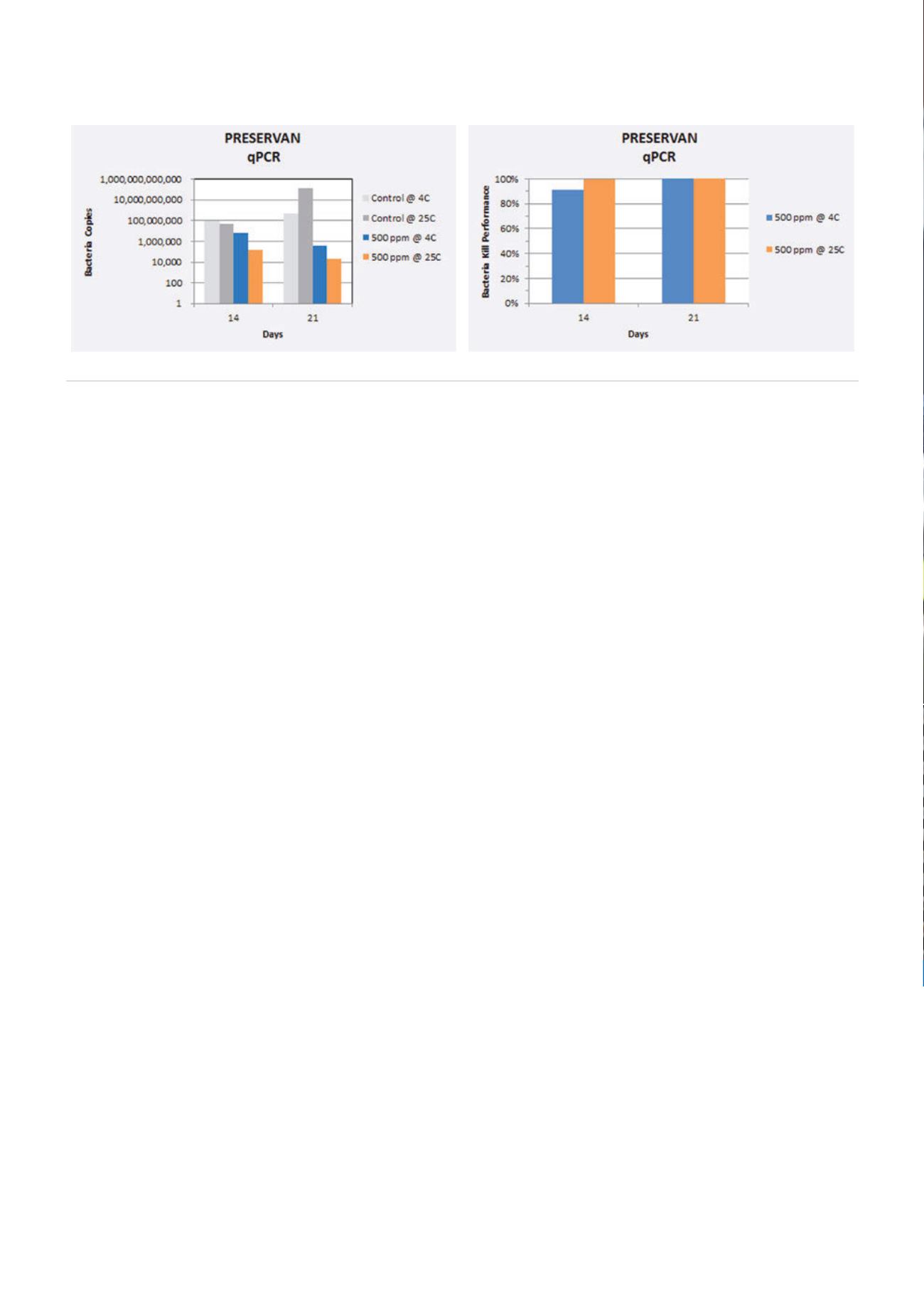

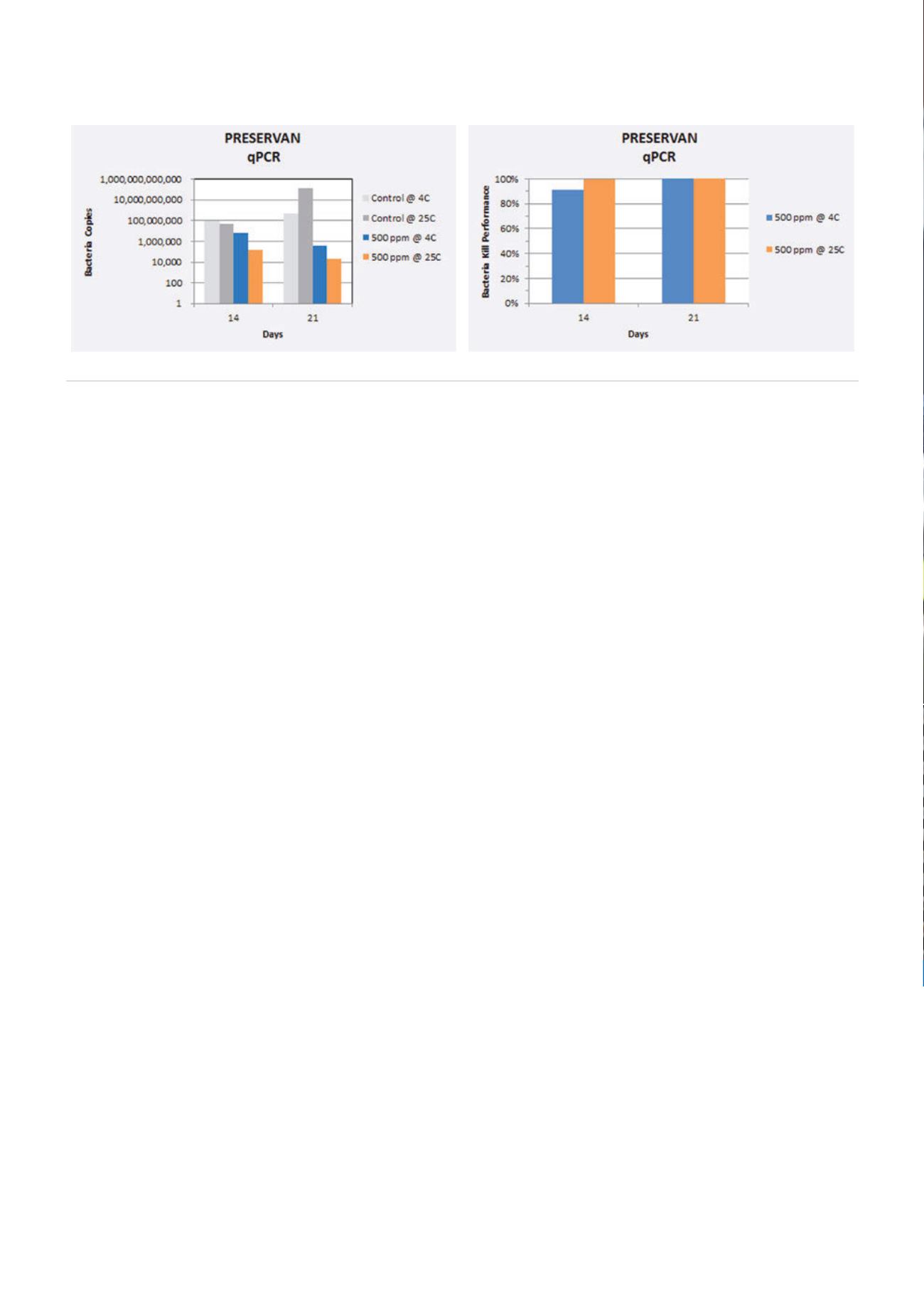

Specialist, best-in-class third-party providers were used for

bacteria testing and included the latest NACE TMO 212-2012

for detection, testing and evaluation of MIC. The state-of-

the-art molecular test method quantitative polymer chain

reaction (qPCR) was selected to test biocidal performance.

qPCR, a modification of end-point PCR, detects amplified DNA

during the PCR process. A highly sensitive camera detects

fluorescence produced by the incorporation of a fluorescent

binding dye in the sample, which gives rise to a more accurate

and precise quantification of DNA. Unlike conventional

culture-based methods such as most probable number (MPN),

qPCR provides a qualitative, highly specific and accurate

determination of active, inactive and even dead bacteria in

any given sample.

To ensure the study was as harsh as possible, all five key

bacteria species responsible for MIC were included in the

qPCR testwork: desulfovibrio desvlfricans (SRB), shewanella

putrefaciens (IRB), thiobacillus thioparus (SOB), pseudomonas

aeruginosa (biofilm) and methanolibacter arachidis

(methanogen).

Results from this test method showed that PRESERVAN

delivered an exemplary kill performance of 99.9% when

compared to the controls at 4°C and 25°C (Figure 3).

Figure 3.

qPCR data shows a 99.9% kill when compared to the controls.

84

World Pipelines

/

JUNE 2015