machine use or productivity

enhancement.

The bolter operators are logged

onto the CYBERMINE mining

simulator using a unique password. As

the operator controls the machine, all

aspects of operation are electronically

monitored and digitally presented,

including adherence to operating and

safety procedures and the operator’s

economic performance. Exercise

results are stored in a comprehensive

database for viewing and printing by

the instructor. The entire bolter

operator training exercise is recorded

for after-action review.

“All simulated vehicle behavioural

dynamics are based on detailed

mathematical models that use vehicle

manufacturer specifications to provide

accurate behavioural realism,”

explained Richard Bellengere,

ThoroughTec’s Vice President of

Operations. “As a result, full collaring,

flushing, drilling, bolting and

tramming tasks are an accurate

reflection of reality. Fortunately we

were able to draw on our experience of

building hard rock bolter simulators,

so many complex problems were

solved already, thus allowing us to put

that effort into improving the

experience. The challenge came in the

layout of the cab and the approach we

took to provide all the functionality on

the motion platform’s limited space.”

Mechanically, the engineering team

were challenged by the sheer volume

of levers that had to be implemented

and fitting them into the limited space

available, with minimal impact on the

realism and ergonomics of the cab.

“But we pulled it off,” continued

Bellengere.

“We’re very pleased with the

accuracy of this particular

CYBERMINE bolter simulator,” said

Bekker. “It’s very realistic and there is

a lot of detail, with operating

procedures built in and we can see it

improving safety and productivity

levels. Even the sound effects are

accurate.” Steyn was equally pleased

with the simulator: “The order in

which all the controls should be

operated and handled is simulated

and measured really well. The

simulator is so close to the real thing,

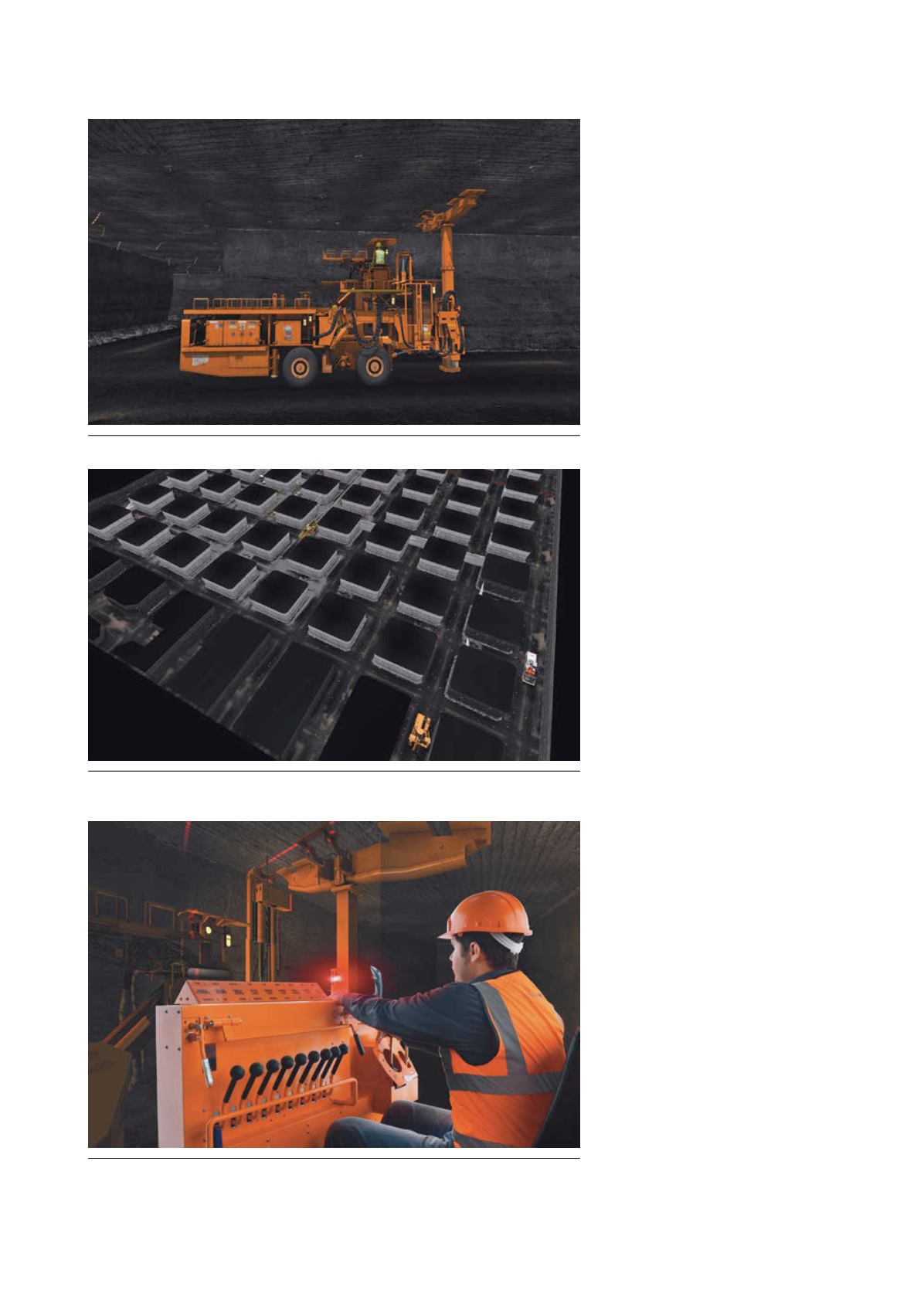

Figure 4. Side view of the Fletcher HDDR bolter preparing to drill and bolt.

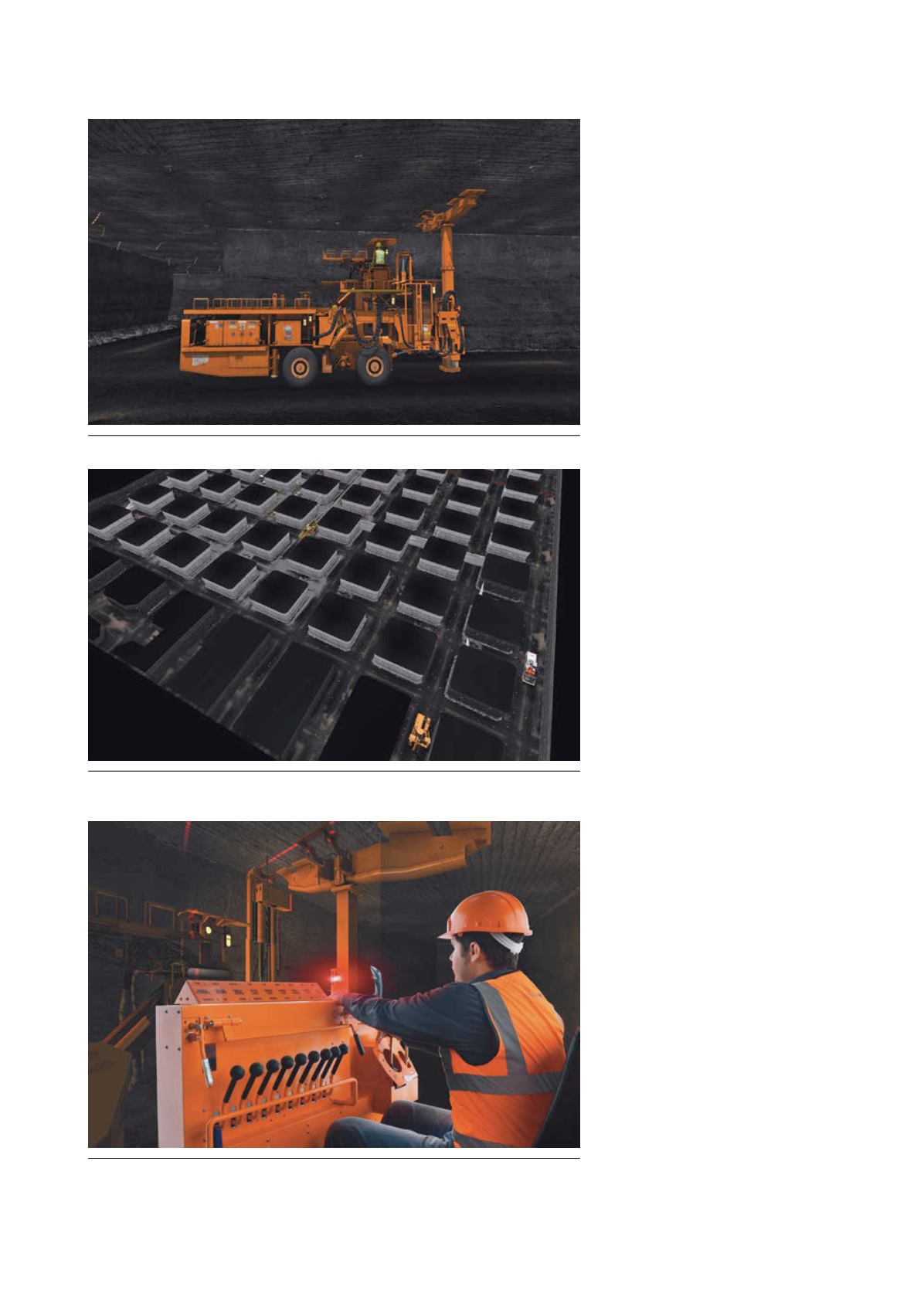

Figure 5. An aerial view of the simulated Khutala mine world showing layout and other

equipment operating.

Figure 6. An operator on the Fletcher HDDR bolter simulator. The controls are

true-to-life for an authentic training experience.

40

|

World Coal

|

June 2015